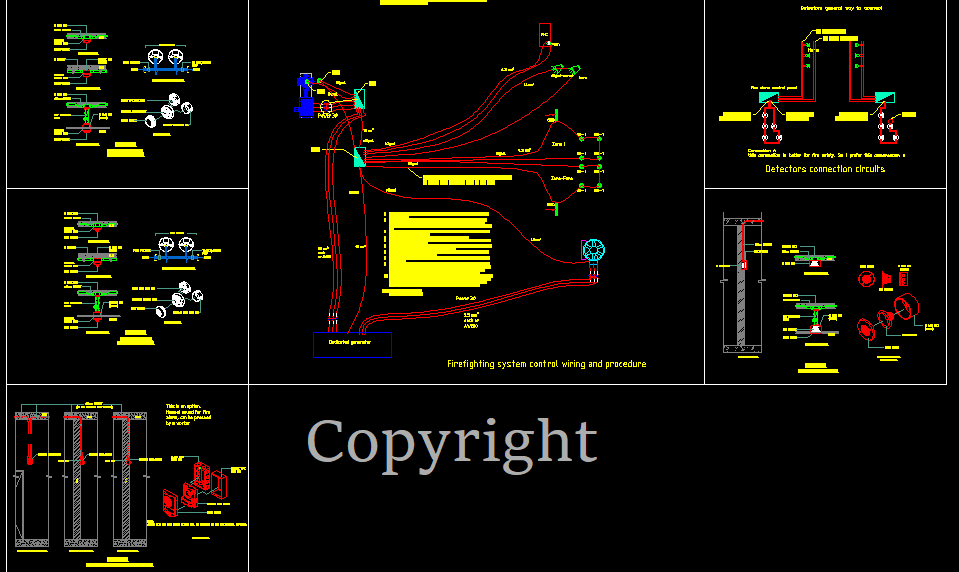

Firefighting pumps room wiring and control diagram. Including detectors and control panel (external simple connection wiring)

Firefighting System Control 17 notes, will appear upon purchase.

Copyright, so you cannot resell or distribute it.

You must log in to submit a review.