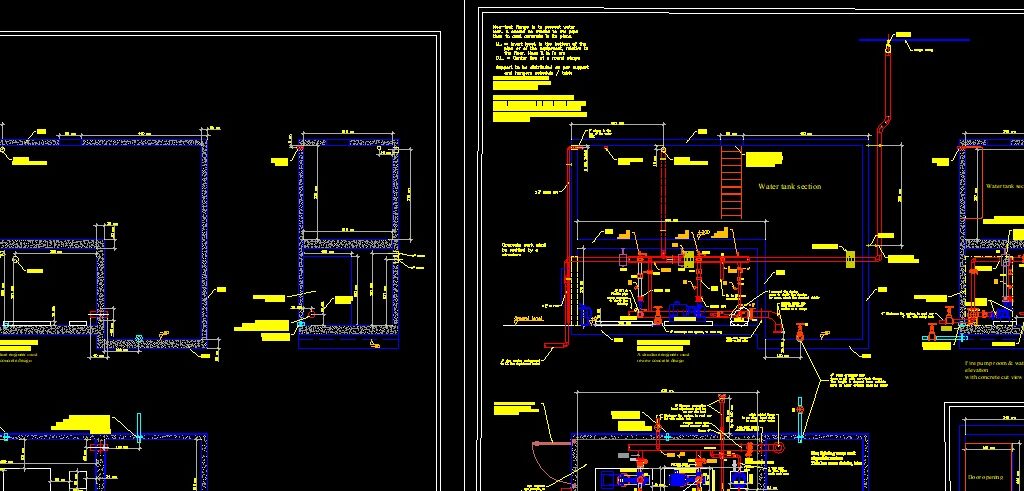

– All required sleeves and openings for the firefighting water tank to fill, discharge, test line, and so many others required.

– The shop-drawing of full firefighting pumps room, top, elevation, and side views or sections. All pipes fittings, accessories, and sensors including wires connection are included. But the control diagram is in a separate plan, by giving a general system.

All parts have names and descriptions.

A full list of points (33) you should take into consideration for fire safety. This will appear upon purchase.

Copyright, so you cannot resell or distribute it.

Reviews

OK

15 of 30 people found this review helpful.

Help other customers find the most helpful reviews

Did you find this review helpful?

You must log in to submit a review.